C4 - Flexible and Efficient Steel Framing Custom Housing Structure Assembly Lines

C4 is a complete just-in-time production line that encompasses assembly, conveyance and material handling of panels in the most cost effective, safe and ergonomic manner. The C4 line can be either implemented for Genesis Solution Providers or as Part of the Coil-to-Panel (CTP) production line combined with the Material Optimization Technology (MOT) for Genesis Licensees.

The C4 line is a combination of lean assembly processes providing optimized productivity for typical and individualized market sectors. Utilizing various levels of automation the C4 ensures that the highest standards of quality are consistently achieved. The line is designed to provide a flexible process flow to efficiently produce wall, floor and roof panels for the residential, commercial and institutional markets. C4 will automatically adjust to the specifications (height, length and number of connections) of a panel with no downtime making it the most flexible and efficient LSF custom assembly platform available.

Quality

- CSA, UL & CE certified, full industrial safety-compliance.

- Floor-Leveling adjustment incorporated on all industrial equipment.

- Heavy duty, robust rollers on all conveyance products.

- High capacity scissor lifts with 35% safety factor minimum.

- Air filter and regulators on all pneumatically activated products.

- Maintenance-friendly design providing easy maintenance access to machinery components without tear down or dismantling.

Flexibility

- Product Manufacturing versatility: wall | floor panel sizes up to 24’ | 7.3 m in height and 18’ | 5.5 m in length, truss span up to 50’ | 15 m

- Single Minute Exchange Die: less than 1-minute machine change over, when required.

- Compact, Modular, Portable machines, that fit into standard shipping trucks or containers, easy to install, re-arrange, move and re-deploy to another facility if required.

- Upgradable framing tables: Three standard sizes of framing tables are available. Smaller tables can be upgraded at any time on-site with minimum production interruption

Other Features

- Auto-quality clamping and squaring of wall and floor panels and trusses, including

“bottoming-out” load monitoring. - Superior Conveyance.

- Built-in-ergonomic handles, devices and fixtures.

- Dedicated Human Machine Interface (HMI) on each automated piece of equipment with start up procedures, production status and user-friendly troubleshooting screens.

- Individual Line output of 35 to 42 wall or floor panels and 24 to 30 trusses per 8-hour

shift with 6 operators

C4: Genesis 4 Step Assembly Process

- Sequencing

- Framing

- Sheathing

- Live Loading

This first stage in C4 can be used with cold formed steel material

purchased from a Genesis licensee or in combination and

synchronization with MOT. The Genesis Material Transfer (GMT) is the

focal point of that link. It consists of a robust maintenance free 2-level

sectional conveyor that allows panel kits to be loaded, conveyed and

unloaded safely. After the panel kits have been produced they move

in sequence for fabrication from the picking or MOT area to the pre-

assembly and fastening areas.

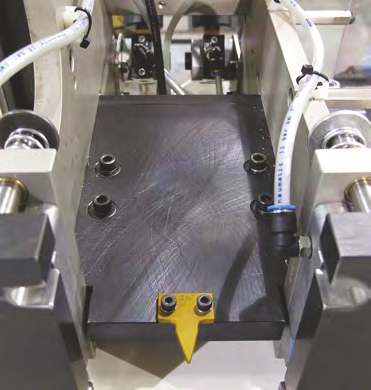

Framing – GFT for Rectangular Panels

This is the second stage of C4 and is a key driver in the efficiency of

the overall process. It provides the most reliable, cost effective and

ergonomic off-site framing technology available in the production of

LSF panels. The one piece of equipment provides a consistent process

for squaring, bottoming out and fastening rectangle panels of infinite

shapes and sizes to a high quality with no down time. The Genesis

Framing Table (GFT) is an unrivalled solution to frame wall and floor

panels (typically under 10 minutes per panel). It provides all tools and

devices needed to quickly load and align components in place, fasten

all connections with screws, without the need to flip the panels.

Framing – GFT for Trusses

GFT for trusses is the solution to framing panels of irregular shapes

(typically under 20 minutes per truss). Similarly to the GFT for

rectangular shapes this unique table provides dimensional and

angular “smart “ devices to allow operators to quickly position, clamp

and fasten all components required for floor panels of irregular shapes

and trusses of any kind (scissors, flat, mansard, jack, common, or

complex). It is also possible to further enhance the speed of assembly

by adding a complete laser system to the GFT as an upgrade.

This third phase in C4 relates to the exterior sheathing of the steel

panels. At this stage custom tables with lateral passage allow workers

to convey the panels safely and with little effort from the fastening

station via a pop up conveyor system. Here a combination of

sheathing (dens glass, OSB, plywood, gypsum, rigid insulation, etc)

can be cut to size and fastened efficiently and with relative ease. The

jigs are combined with the latest nailing technologies for fixing multi-

layer material such as dens glass and gypsum into steel members.

GEM rigidly controls the sequencing of the panels throughout the

entire manufacturing process based upon a site delivery schedule.

Panels can be grouped in work orders or by site block number to

ensure that the panels delivered to site are those which are to be

erected first. Prior to being loaded a final inspection takes place. Once

the panels have been bundled and strapped into groups ready for

dispatch (typically 6-12 panels) a custom lifting device attached to an

over head crane loads them safely onto trucks within the plant.

©2024 Genesis Housing Copyright All Right Reserved.